Postharvest ginger

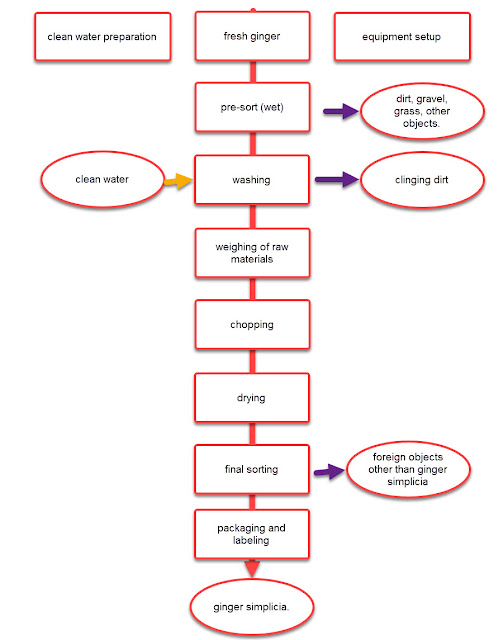

Post-harvest is an action taken after harvesting ginger, starting from cleaning the crop from unwanted dirt, soil and microorganisms through washing, sorting, chopping, drying, packaging to storage. The aim is to produce products that are shelf-resistant, of good quality by maintaining the content of active ingredients that consistently meet quality standards.

Basic Information

- Post-harvest is carried out to produce fresh products and simplicia. The stages of making simplicia include:

- Preparation of raw materials;

- Preparation of equipment and packaging materials;

- Processing;

- Packaging and labeling

- Storage;

- The raw material in the manufacture of ginger simplicia is fresh ginger rhizome from the harvest which is large and old enough (8-10 months) still fresh, not rotten and not damaged / defective;

- Packaging equipment and materials:

- Container / tub / bucket;

- Plastic brush;

- Plastic basket;

- The blade does not rust;

- Chopper mat;

- Dryer: tampi bamboo, solar dryer (sunlight);

- Para-Para (Rack);

- Recommended shelf materials are aluminum or stainless steel;

- Balance;

- New packaging (sacks, plastic bags, barrels / corrugated fiber drum);

- Label.

Processing via:

Initial sorting (wet)

Sorting is done to separate good ginger rhizomes from rotten / damaged ginger rhizomes or other foreign contaminants and will be processed / packed in the form of simplicia and fresh ginger rhizomes.

Washing

Washing is done with a plastic brush carefully to remove dirt from the crops and reduce microbes that stick to the ginger rhizome. Washing is carried out in stages (in multilevel wash basins). Efforts are made to make efforts to use the washing place to use running water so that the rest of the washing is immediately wasted.

Weighing of materials

The selected rhizomes are weighed. Weighing is carried out to determine the net weight of the material being processed.

Chopping

Chopping is done to speed up drying done longitudinally. Chopping is done using a chopper machine or manually with a uniform chopping direction with a thickness of 4 - 6 mm or according to market demand. The size of the chopping thickness greatly affects the quality of the simplicia material. If it is too thin it will reduce the active ingredient content and if it is too thick it will complicate the drying process.

Drying

Drying through the sun drying process. Striving for drying places in a place that does not allow dirt / other objects to enter (at least 20-30 cm above the ground). If the drying is not complete, then dry it the next day until the moisture content is around 10%. Drying is a very important process in the manufacture of simplicia, because in addition to extending the storage capacity it also determines the quality of the simplicia.

Final sorting (simplicia)

The final sorting is done by quality. After sorting, it is weighed to calculate the yield from processing.

Packaging and Labeling

After the simplicia has reached the desired degree of dryness, it can then be packed immediately to avoid re-absorption of moisture. Strive to ensure that packaging materials / bags are clean and tightly closed. Materials that have been completely dry are put into bags and labeled with the name of the simplicia type. Try not to make sure the contents of the bag are too tight / dense or not pressed. Take care not to stack bags that contain dry simplicia, or there must be an bulkhead between the piles.

Storage

Storage is carried out in a clean room / warehouse with good air circulation and not humid, away from other materials causing contamination and free from warehouse pests. If the storage is good and correct, the product can be stored for up to 10 months.

Work procedures

Initial sorting (wet)

- Choose ginger rhizomes that are large, old (8 - 10 months old), good, not rotten / damaged or exposed to other foreign substances;

- Clean the ginger rhizome from the soil and other dirt that is still attached, by beating it slowly;

- Cut the leaves, stems and roots using a knife;

- Separate the rhizome material to be processed / packed in the form of simplicia and fresh ginger rhizome material.

Washing

- Wash the ginger rhizome by brushing slowly and regularly under running water and rinsing under running water;

- Drain in a plastic basket;

- Weigh the selected rhizome material.

Chopping

- Slice the ginger rhizome using a chopper machine or manually. Unidirectional chopping direction. 4 - 6 mm thick or according to market demand;

- Collect the ginger slices into the container.

Drying

- Prepare drying tools / facilities; Drying ingredients that can be used to dry ginger slices are:

- Sunlight in the shade (can use paranet;)

- Solar-powered drying equipment (solar driyer), or

- Pegering machine (tray driyer).

- Lay the ginger slices on the dryer evenly. Especially for the tray driyer, the maximum thickness of the stack is 5 cm;

- Set the drying temperature to 50 0C - 60 0C; d) Remove simplicia from the drying mat after the moisture content reaches 10%.

Final Sorting (simplicia)

- Remove foreign objects and other impurities that are still left behind;

- Weigh the simplicia after sorting to calculate the yield of the processing.

Packaging and Labeling

- Prepare packaging materials;

- Weigh the simplicia of ginger for each package (net weight);

- Do the packaging carefully so that the packaging is not crushed;

- Close the package tightly. For plastic packaging, seals can be used;

- Give a label on the packaging.

Storage

Storage is carried out in a clean room / warehouse with good air circulation and not humid, away from other contamination-causing materials and free from warehouse pests.

- Keep the packaged products in a clean room / warehouse and the air circulation is good and not humid, away from other materials causing contamination and free of pests;

- If the storage is good and correct, the product can be stored for up to 10 months.

|

| Simplicia Ginger Processing Flow Chart. |